Keps

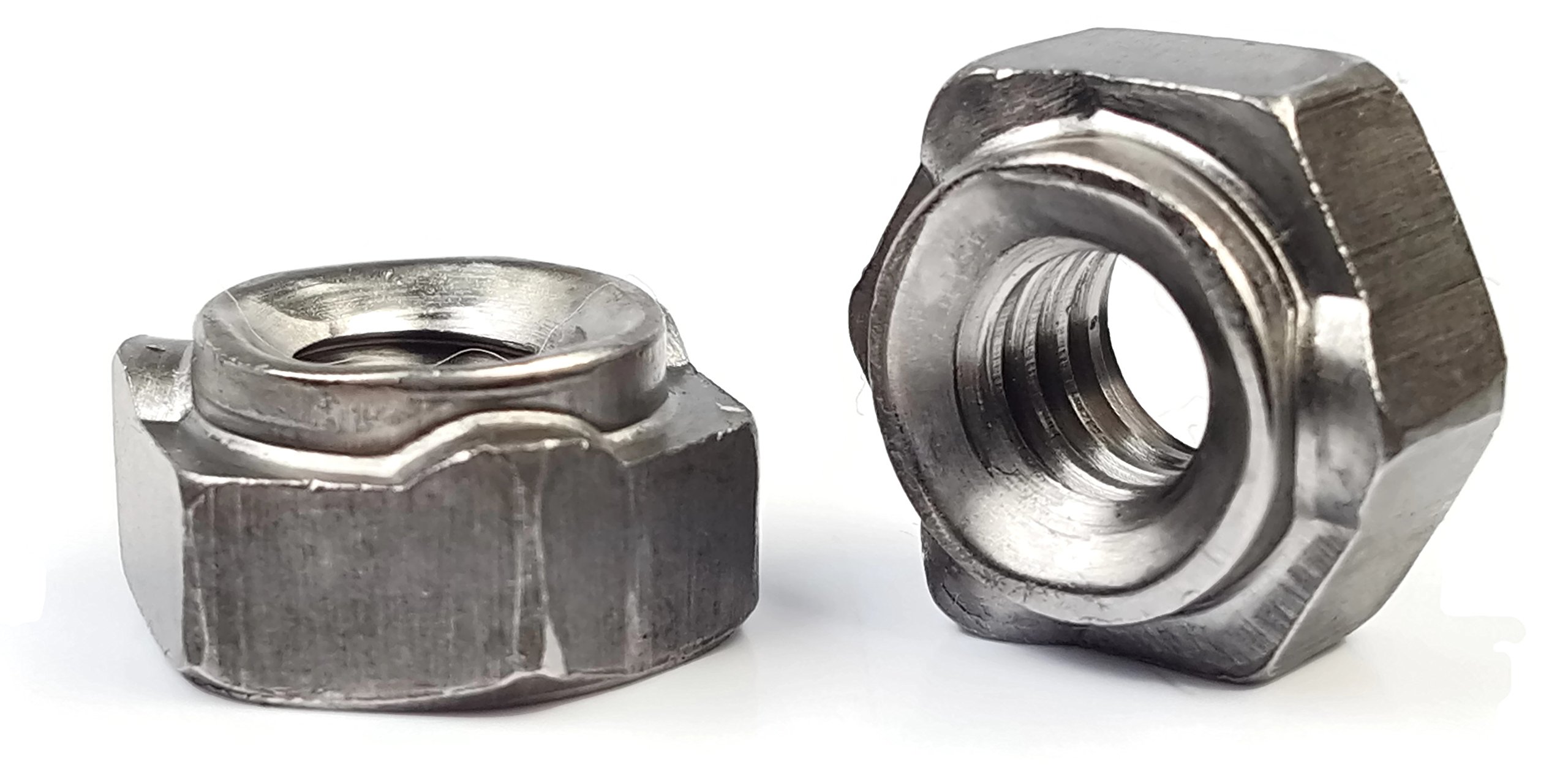

A keps nut, also known as a K-nut or washer nut, is a type of fastener that combines the functions of a nut and a washer. It is designed to provide a secure and reliable fastening solution in applications where vibration and movement are common.

The keps nut has a standard hexagonal shape, similar to a regular hex nut, with internal threading to match the threads of bolts or screws. What sets the keps nut apart is the added washer-like feature on its base. This built-in washer, often in the form of an external toothed or serrated flange, is attached to the bottom surface of the nut. The flange is slightly larger in diameter than the nut itself and contains teeth or serrations that grip the surface of the mating material.

The key benefit of the keps nut is its ability to resist loosening due to vibration and other external forces. When tightened onto a bolt or screw, the serrated flange bites into the material's surface, creating friction and preventing the nut from rotating freely. This provides a secure locking effect, reducing the risk of the fastener coming loose and maintaining a tight and stable connection.

Keps nuts are commonly used in various industries, such as automotive, electronics, and machinery, where reliable fastening is essential. They are particularly favored in applications that experience constant movement, such as vehicle engines, industrial equipment, and electrical enclosures.

When installing keps nuts, it's important to ensure that the serrated flange is facing the mating material to achieve the desired locking effect. This will help maintain a secure connection and prevent unintended loosening, contributing to the overall safety and performance of the assembled components.

SCREWS

SCREWS

NUTS

NUTS

BOLTS

BOLTS

WASHERS

WASHERS

SPACERS & STANDOFFS

SPACERS & STANDOFFS

PRECISION/CUSTOM PARTS

PRECISION/CUSTOM PARTS

PINS

PINS

WIRE HANDLING

WIRE HANDLING

INSERTS

INSERTS

ANCHORS

ANCHORS

DRILL BITS, TAPS, & DIES

DRILL BITS, TAPS, & DIES

ABRASIVES & SAWBLADES

ABRASIVES & SAWBLADES

SAFETY EQUIP.

SAFETY EQUIP.

MISC.

MISC.

MATERIAL TYPES

MATERIAL TYPES

PLATING TYPES

PLATING TYPES