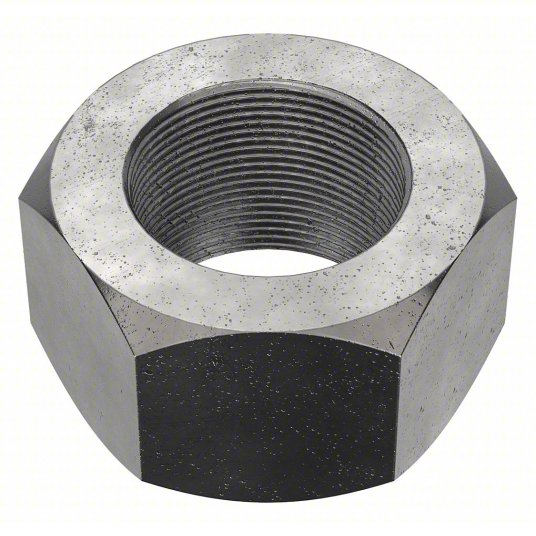

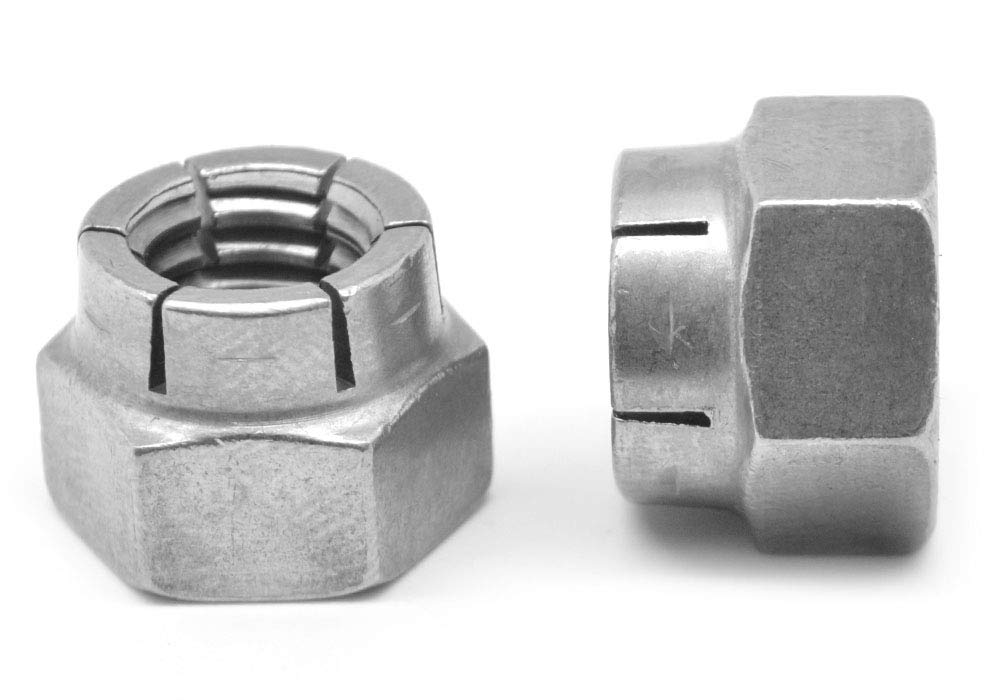

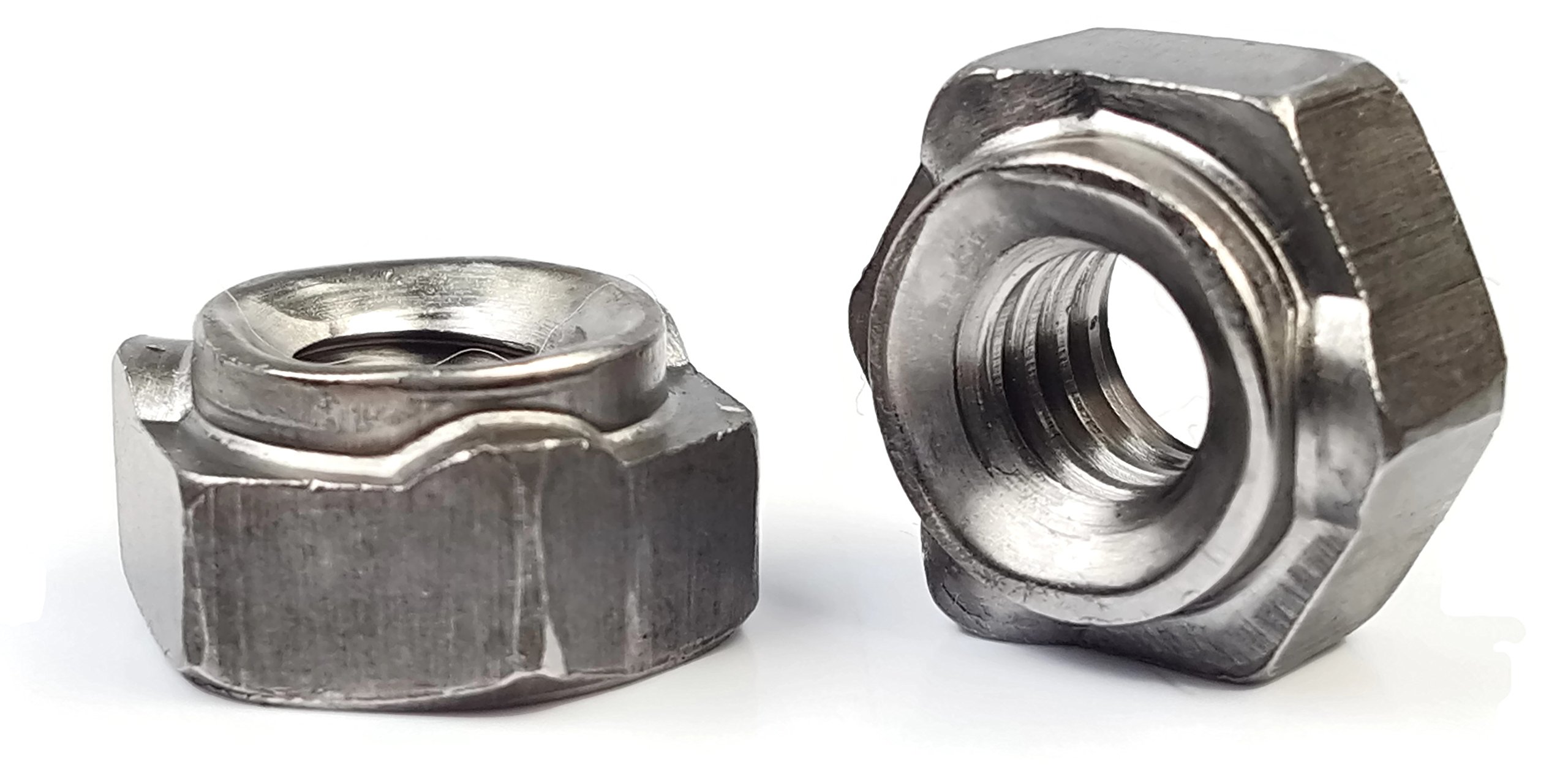

Serrated Lock

A serrated lock nut, also known as a serrated flange nut or a serrated washer nut, is a type of fastener designed to provide resistance against loosening due to vibration, movement, or external forces. It incorporates serrations (grooves or ridges) on the bearing surface of the nut that dig into the mating surface, creating friction and preventing the nut from rotating freely.

Key features of a serrated lock nut include:

-

Serrated Surface: The bottom or bearing surface of the nut is equipped with serrations, which are small grooves, ridges, or teeth. These serrations are designed to dig into the material of the mating surface (such as the workpiece or the surface being fastened), creating resistance against rotational movement.

-

Flange Design (Optional): Some serrated lock nuts have a flange at the bottom, which is a flat, circular extension that provides a larger bearing surface. The flange can distribute the load and reduce the risk of damaging the mating surface.

-

Materials: Serrated lock nuts can be made from various materials, including steel, stainless steel, and other metals. The choice of material depends on factors like strength requirements and environmental conditions.

Serrated lock nuts are commonly used in applications where vibration and movement could cause conventional nuts to loosen. They offer advantages in terms of providing additional resistance to rotation without the need for separate locking components such as washers or adhesives. Examples of industries and scenarios where serrated lock nuts are utilized include automotive, machinery, equipment assembly, and industrial applications.

SCREWS

SCREWS

NUTS

NUTS

BOLTS

BOLTS

WASHERS

WASHERS

SPACERS & STANDOFFS

SPACERS & STANDOFFS

PRECISION/CUSTOM PARTS

PRECISION/CUSTOM PARTS

PINS

PINS

WIRE HANDLING

WIRE HANDLING

INSERTS

INSERTS

ANCHORS

ANCHORS

DRILL BITS, TAPS, & DIES

DRILL BITS, TAPS, & DIES

ABRASIVES & SAWBLADES

ABRASIVES & SAWBLADES

SAFETY EQUIP.

SAFETY EQUIP.

MISC.

MISC.

MATERIAL TYPES

MATERIAL TYPES

PLATING TYPES

PLATING TYPES